A comprehensive manufacturing guide to filling cartridges without leaks.

Why do vaporizer cartridges leak? It is a question that has everyone point fingers at each other on what the real culprit is. Is it the oil, terpene, substandard hardware, filling technique, or just plain users leaving their cartridges in a hot car? This topical is designed to deconstruct major aspects of leaking cartridges so lab directors can reduce chargebacks and increase customer satisfaction with their products When first started investing in the regulated products space in 2015 one of the first people I met presented me with a cartridge and was told that this piece of plastic and metal was one of the biggest problems in the industry. Fast forward more than half a decade, multiple investments into extraction, manufacturing, and distribution to some of the largest vape companies in the USA, I have aggregated a list of items that impact vaporizer leakages.

What Causes Leaks?

Loss of vacuum lock – is the answer. Regardless of the reason, something, someone, or some event caused the vacuum lock to release. Modern cartridges are designed with a vacuum lock principle and to prevent cartridge leaks, lab directors can in many cases use a combination of the manufacturing process and formulation modification to prevent leaks from occurring. When the cartridge draws fluid down initially into the vaporizer, a small vacuum forms on the top of the reservoir, this vacuum essentially “holds” the extracts in the oil chamber while the outside pressure pushes the against the extracts holding it inside. The 3 main areas that cause leaks (vacuum loss) are: Filling Technique Errors – long cap times, defective capping, slanted capping Extract Formulation – Excess terpene & dilutant loads, live resins mixtures, rosin degassing, User Behavior – Flying with cartridges, hot cars.

Manufacturing Errors and how it causes leaks

1.Not capping fast enough: Slow capping results in no vacuum lock forming or a weak vacuum lock taking effect. The time required to form a vacuum lock depends on the temperature (both extract and temperature of the cartridge) and viscosity of the extract being filled. The general rule is to cap within 30 seconds. The fast capping technique ensures that a vacuum lock can form when the cartridge is capped. Until the cap is installed on the cartridge, the extracts are exposed to the atmosphere, during this process the extract is soaked into the reservoir and if not capped, all the extracts will flow out of the cartridge. This effect is noticeable in filling machines that fill cartridges but do not cap – where the first cartridges filled are starting to leak as the last few are being filled.

Mitigation procedures:

The obvious procedural is to secure the cap as fast as possible. However, if for some reason you cannot do this then you can mitigate with the below.

●Use more potent extracts (in the 90% potency with 5-6% terpenes) to increase viscosity. This increases the thickness of the final formula and will extend the time needed to cap.

●Lower filling temperatures to 45C will extend the time needed to cap. This will not work for very dilute solutions where most cartridges require capping with 5 seconds.

2.Defective-capping/capping technique: Capping technique is something most lab directors miss when they are evaluating leakage rates. Miss capping usually involves 1) Pressing the cap down at an angle or 2) Mis thread that deforms the inside of the cartridge not allowing the cartridge to seal properly.

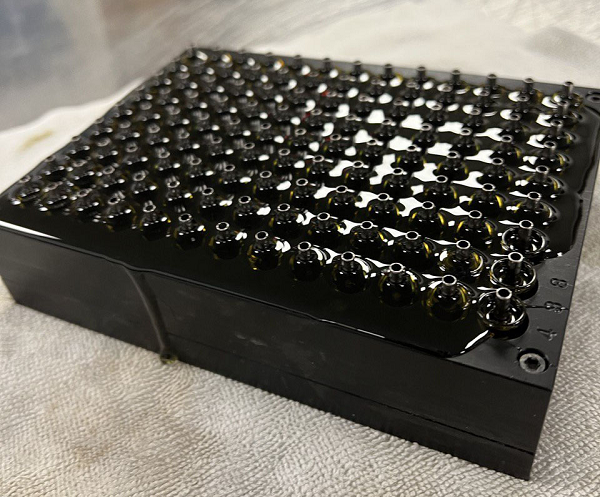

Here is an example of angled clamping – when the cap is forced down at an angle. Although the cartridge looks undamaged from the outside, the center post alignment and the inside seals have been damaged compromising the sealing capability of the cartridges. Duckbill and cartridges with irregular caps have the highest probability of mis-caps. Miss-threads are from threads not fitting when screwed together. This misalignment causes the seals to be warped when locked together leading to vacuum loss.

Mitigation procedures:

●For manual labor lines: using a large format arbor press – large-format arbor presses (1+ ton-force) are easier to operate and have a large pully. Contrary to public perception, the greater downforce actually allows smoother action by the assembly personnel leading to fewer defective caps

●Choose caps like barrel and bullet designs that are easy to cap in all situations. Having easy-to-cap mouthpieces makes the capping process easier for all processes and personnel.

Extract formulations and how it impacts leaks

●Overuse of dilutants, cutting agents, and excess terpenes: Extract purity and final formulations have a great impact on the leakage rate. Vaporizers for highly viscous extracts like D9 and D8 are designed for such materials and the addition of dilutants above normal terpene loads negatively impact the core and absorbent cellulose. Dilutants like PG or MCT oil weaken the extracted matrix leading to bubbles forming at the core that can travel to the main oil reservoir and break the vacuum seal.

●Live Resin – Excess terpene layer usage and improper degassing: Many people have reported live resin leakages in the past. The main culprit (assuming hardware and filling technique is correct) is the excess use of the terpene layer from a crystalized live resin. Typically, the live resin needs to be mixed with the distillate in a 50/50 distillate to live resin ratio to form a final mixture. The terpene layer itself (an extremely desirable product) is not viscous enough to be held inside a cartridge. Formulation scientists often in their desire to create a more premium product overuse the terpene layer leading to excess terpenes that weaken the vacuum lock of the cartridge. Other more serious issues can excess residual butane becomes released when the vaporizer starts to get warm from use. Excess butane needs to be removed during the extraction at a laboratory facility.

●Rosin – Improper light aromatic degassing: Similar to live resin – Rosin needs to be degassed and crystallized prior to formulation with distillate. The issue with rosin is the light aromatics that are present – these light aromatics (some completely flavorless) will evaporate and cause pressure during cartridge activation causing the cartridge to break vacuum lock and leak. Proper degassing is critical to ensure that stable rosin is useable for vaporizer cartridges.

Mitigation procedures:

Dilutants, cutting agents, and excess terpenes:

●Use high-quality distillate in the 90% range or higher to preserve viscosity.

●5%-8% total terpene addition across all flavors to keep dilutants low.

Live Resin:

●50%/50% – 60%/40% Distillate to live resin ratio (terp layer mix). Any terp percentage greater terps risks leaks – any lower than 40% risks flavor dilution.

●Ensure proper residual butane evaporation in a near-vacuum @ 45C.

Rosins:

●Properly degas light aromatics terpenes @ 45C – these light aromatics (although mostly flavorless) can be cold trapped and recollected for dabble products if desired.

User Behavior and how it impacts leaks and how to counteract it

Any time you leave something in a heated area, you’re very likely to have physical reactions occur. Every time users fly with cartridges the low pressure of a plane weakens the vacuum lock. Whether it is simple to pressure change or as complex as chemical reactions that denature the terpenes causing off-gassing, users put a lot of stress on cartridges. Formulators can offset some but not all the events users put their products through.

Cartridges in a hot car:

Hot temperature averaging around 120F or 45C causing vacuum locks to fail.

Mitigation techniques:

Standard distillate cartridges: Formulations – was a 90% purity distillate used with a 5-6% terpene load are the most survivable in this condition Live Resin: Assuming users will still want to use a live resin cartridge after this event (live resin will denature after 3 hours at 45C) a 60% distillate 40% live resin cartridge will be more resistant to leaks. If temperatures rise about 45C for live resin, there is a high chance of leaks due to terpene off-gassing in the cartridges Rosin: Assuming users will still want to use a live Rosin cartridge after this event (Rosins are even more sensitive due to inherent plant waxes and will denature after 3 hours at 45C) a 60% distillate 40% rosin cartridge will be more resistant to leaks. If temperatures rise about 45C for live resin, there is a high chance of leaks due to terpene of gassing in the cartridges.

Airplane rides:

Reduced atmospheric pressure causing the vacuum lock in the cartridge to fail.

Mitigation strategy 1:

Pressure resistant packaging – this integrally sealed packing prevent pressure change to affect the cartridge. Honestly, this is one of the best solutions for transport whether it be for air travel or even distribution trucks driving up some mountains.

Mitigation Strategy 2:

Standard distillate cartridges: Formulations use a 90% purity distillate used with a 5-6% terpene load are the most survivable in this condition Live Resin: Using a 60% distillate 40% live resin cartridge will be more resistant to pressure-induced leaks. Rosin: 60% distillate 40% rosin cartridge will be more resistant to pressure-induced leaks.

Post time: Jun-22-2022